To optimize the industrial logistics operations

CLIENT

A major European pulp & paper industry player. Our customer carries out wood harvesting, transportation, cutting and processing and produces product pulp, cardboard and paper.

CHALLENGE

The customer delivers trucks of timber to the specialized logistics centers for subsequent shipment to the mills.

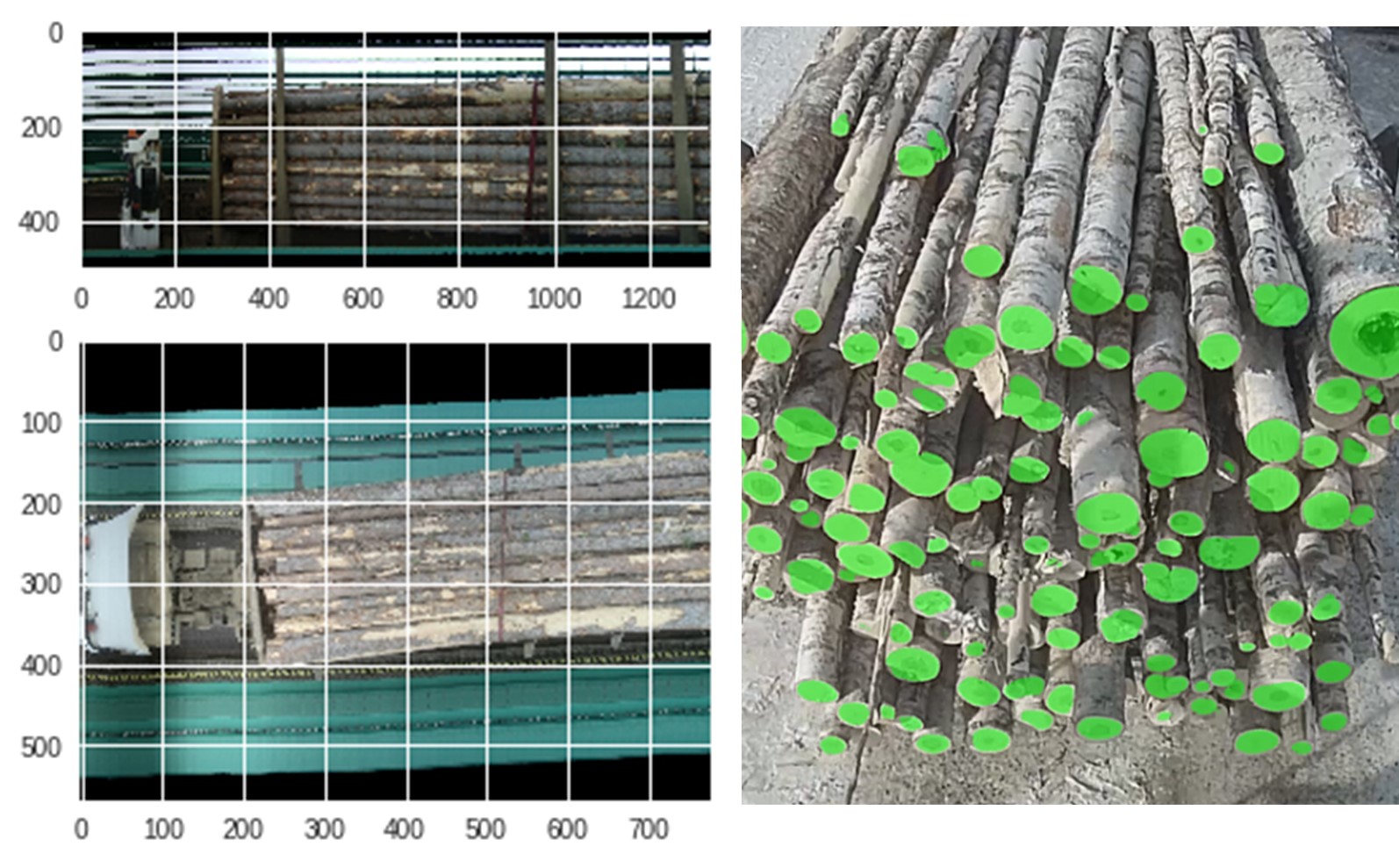

One of the key goals when accepting wood at the logistics center is to determine the packing density and the type of wood. To provide higher throughput, special photo frames — scan tracks — are used at the checkpoints. When a loaded timber truck passes through them, it is photographed in three projections. Based on these photos, inspectors manually determine the packing density and wood type. This approach has led to errors and higher personnel costs.

The client needed to:

To tackle these issues, we have developed a system for automatic measurements of timber volume based on photo analytics and machine learning.

SOLUTION

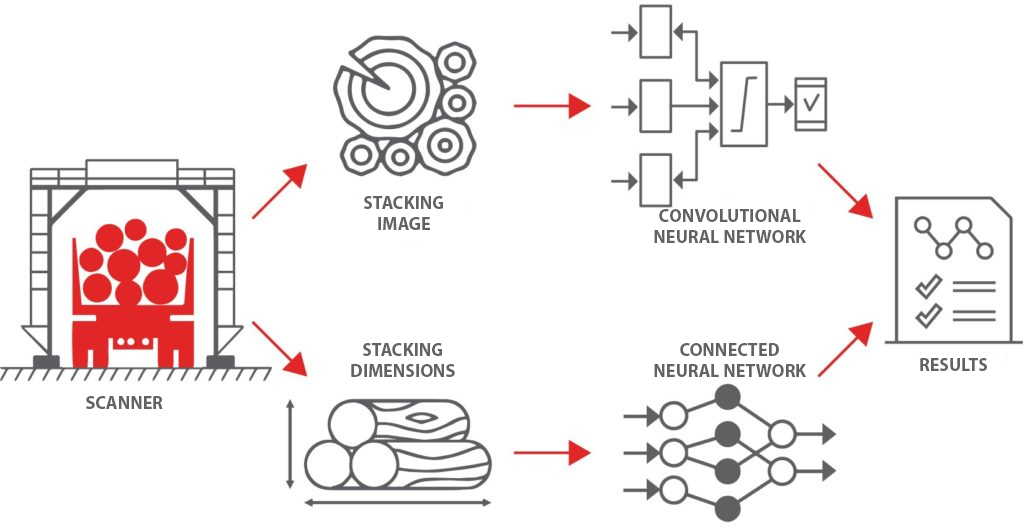

Reksoft specialists have created a model that allows the customer to accurately measure the stacking density and identify wood types at the reception points of timber. The system is built on photo analytics and machine learning technologies based on advanced deep neural networks.

Network topology

The outputs of these networks are combined into another fully connected layer, which calculates the stacking density factor. The type of wood is determined by a convolutional neural network. It analyzes the photo and, based on authentic features, gives the probabilities of the depicted wood can be, for example, birch or aspen. The system selects the most likely option.

The data of one timber truck passing through the scan track is processed within a few seconds, whereas previously the process could take a long time, and the estimation accuracy was at a significantly lower level.

The network is trained by manual corrections: if the prediction is wrong, then the parameters are rearranged so as to correct the estimate. This happens until the error percentage is reduced to the required value. In the future, when new data and new errors appear, the network will retrain on its own.

The model is implemented in Python, the deep learning framework is using PyTorch. Basic architecture of convolutional network: se-resnext101, optimization algorithm: Adam, loss function: mean absolute error.

OUTCOMES

To increase the accuracy, Reksoft specialists continued training the neural network. This allowed more data to be collected and “reference” images to be created. At the moment, the solution is planned to be launched as an industrial version for its integration with 13 scan tracks of the enterprise facilities in Europe.

The developed system makes it possible to reduce the influence of the human factor, shorten the assessment time and significantly optimize the logistics process. In addition, the solution can help form a common standard for the application of machine learning methods and can be used for other sites, raw materials options and types of logistics.